The analyzer is built directly into the conveyor line for continuous quality control of coal and coke in real time. Does not require calibration by coal or coke brand.

For what:

Sorting of raw coal by impurities and ash content directly from the face or quarry.

Profit:

Optimal distribution of coal along technological streams and effective planning of enrichment.

For what:

Constant control of characteristics of incoming raw coal.

Profit:

Automatic adjustment of enrichment parameters for maximum yield of high-quality concentrate.

For what:

Final quality control of concentrate before sending to the consumer.

Profit:

Guaranteed compliance of concentrate with declared parameters (ash content, calorific value, moisture).

Real-time data is transmitted to the production management system

Works with coal of any size class up to 300 mm

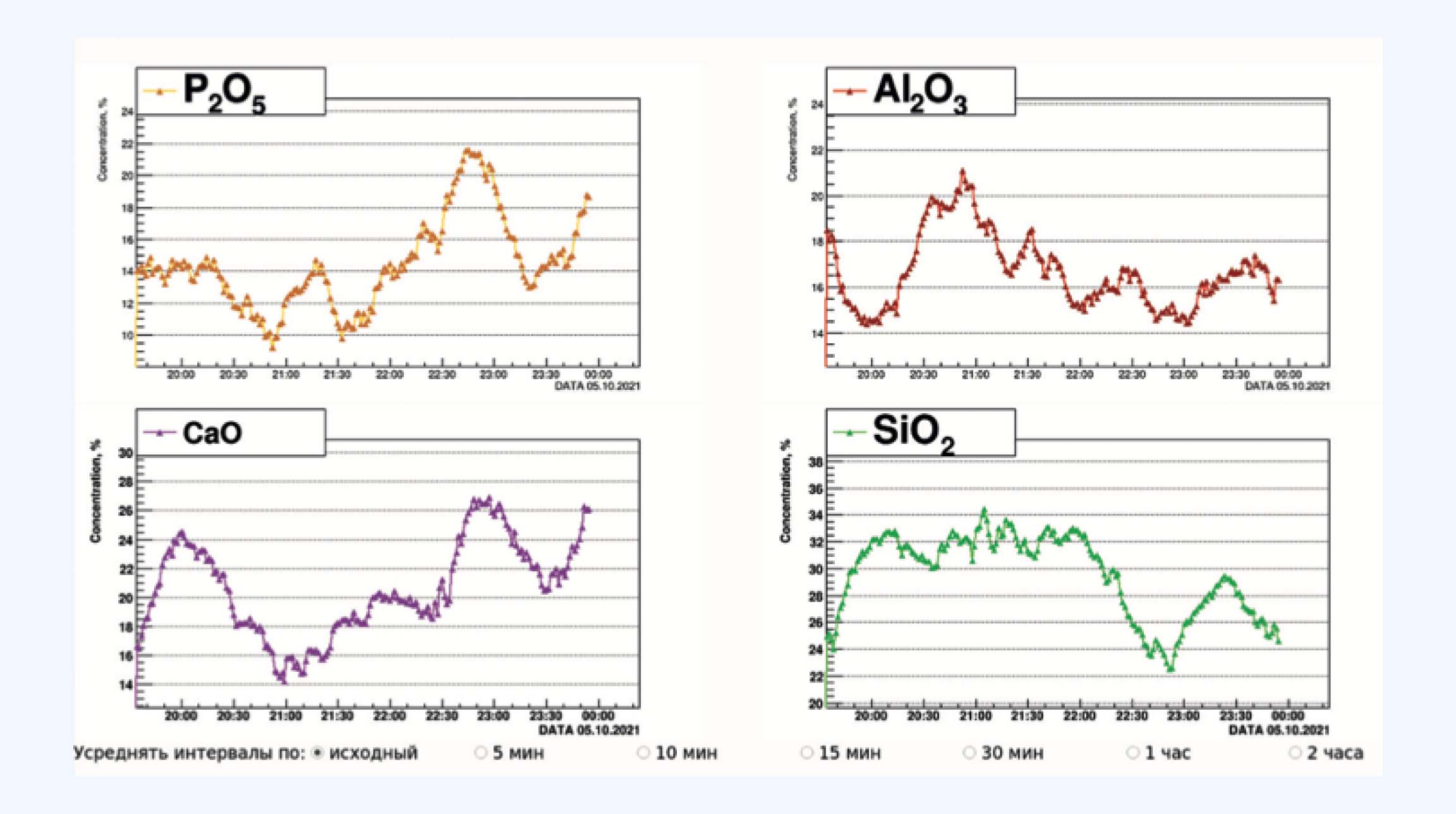

Measures key parameters without sampling every 40-60 seconds

Works with any coal brand at any ash and moisture ranges. No separate sub-calibration for different raw materials is required.

The analyzer is installed under the conveyor — the entire coal flow passes through it

Continuous control of ash content, moisture, calorific value without need for additional determination of coal brand

Optimization of processes of enrichment and blending of coals

Stable quality of finished products

Cost reduction for laboratory analysis and sampling

| Element | Coarseness, mm | σr , % | σr relative, % |

|---|---|---|---|

Mass concentration of carbon |

0 - 2020 - 100 | 0,160,12 | 0,290,23 |

Ash content |

0 - 100 | 0,13 | 0,35 |

Humidity, Wr , % |

0 - 20 | 0,64 | 4,57 |

Specific (lower) heat of combustion, Qi , kcal/kg |

0 - 20 | 59,4 | 1,14 |

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание