The analyzer is built directly into the conveyor line at the processing plant for continuous real-time quality control of phosphate ore.

For what:

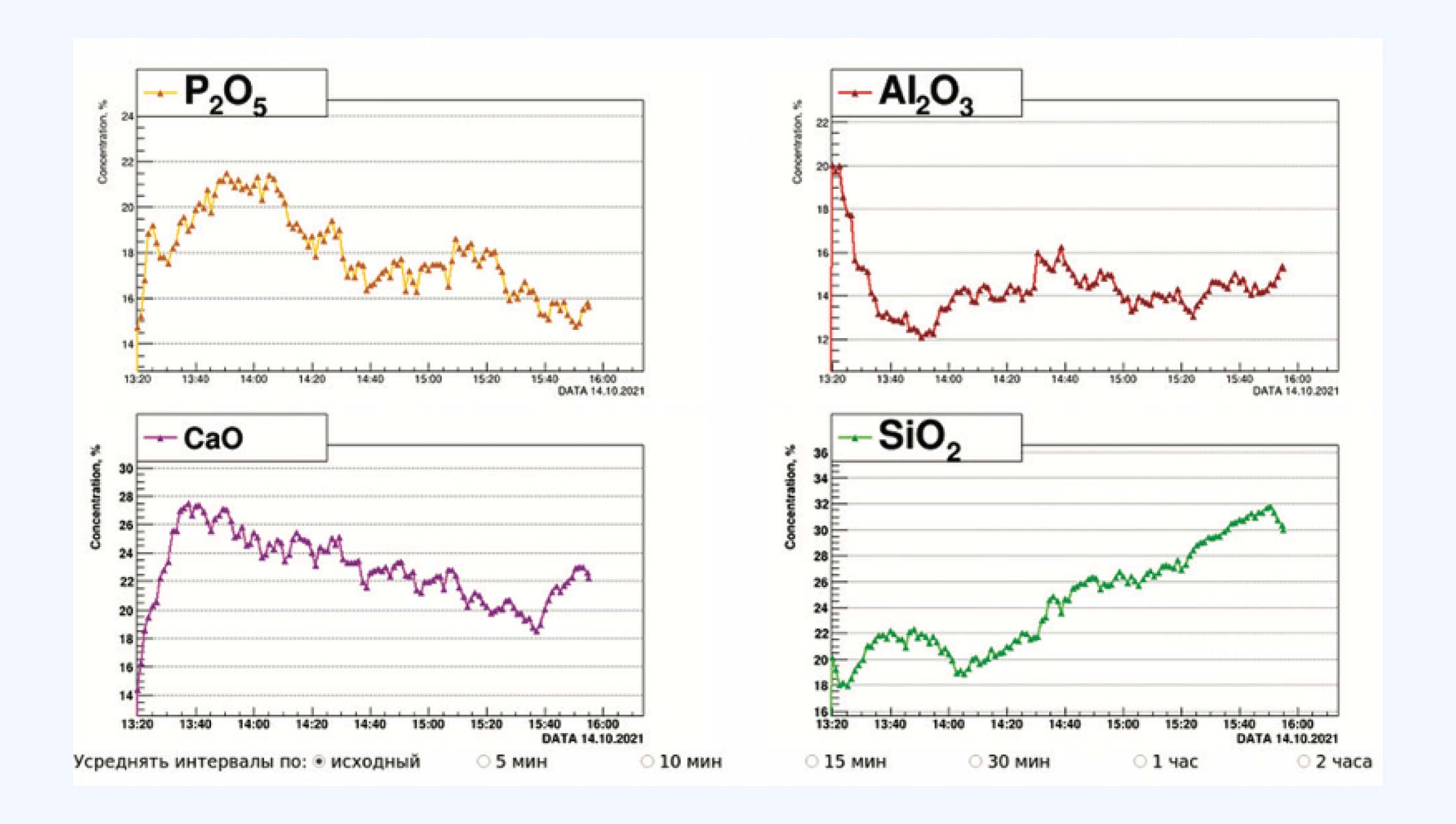

Constant monitoring of the composition of incoming ore.

Profit:

Quick determination of raw material grade for optimal distribution along technological chains.

For what:

Control of P₂O₅ content in crushed ore before enrichment.

Profit:

Ore grading and operational management of the enrichment process.

For what:

Final quality control of products.

Profit:

Guaranteed compliance of the concentrate with the requirements of standards and technical conditions.

The analyzer is installed under the conveyor — the entire ore flow passes through it.

Measures composition without sampling every 40-60 seconds.

Works with material of any size up to 300 mm.

The data is transmitted to the production management system.

Continuous control of P₂O₅ content and other impurities

Operational management of the enrichment process

Stable quality of finished concentrate

Cost reduction for laboratory analysis

| Element/ Oxide | Measurement uncertainty |

|---|---|

| P205 (repeatability) | 0,25% (absolute standard deviation) |

| P205 (convergence with chemical analysis results) | less than 5% (relative standard deviation) |

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание