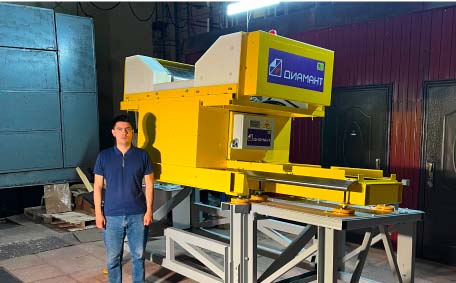

The analyzer is built directly into the conveyor line at the sinter plant to control the composition of the charge before it goes to sintering.

For what:

Check the composition of the whole mixture (ore, limestone, coke) after mixing. This is the last opportunity to adjust the formulation before sintering.

For what:

Final, fastest control. The analyzer shows the charge composition in real time just before sintering, allowing the properties of the finished product to be predicted.

The analyzer is placed directly under the conveyor — all material passes through it.

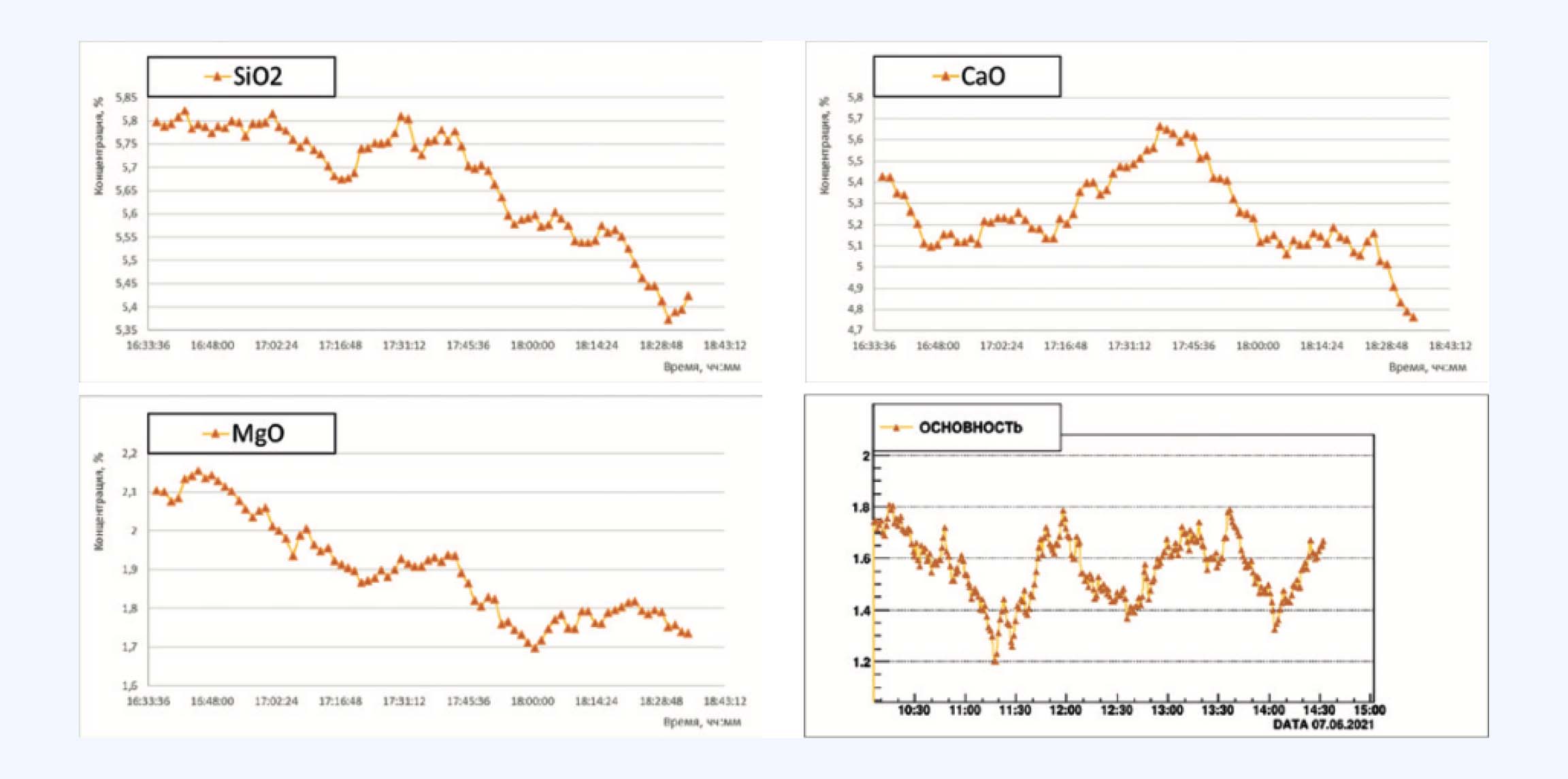

It continuously measures the composition without sampling, every 40-60 seconds.

The data is immediately transmitted to the operator's computer or to the shop floor automation system.

Stable quality of sinter due to constant control of basicity (CaO/SiO₂).

Saving coke due to precise

carbon control.

Reduction of waste and

raw material overconsumption.

| Element/ Oxide | Content range, % | Measurement uncertainty |

|---|---|---|

| CaO | 4 - 12 | 0,3 |

| SiO2 | 2 - 8 | 0,3 |

| C | 2 - 7 | 0,3 |

| Fe | 54 - 62 | 0,5 |

| MgO | 0,5 - 3,5 | 0,3 |

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание