The analyzer is built into the conveyor line of the cement plant for continuous quality control of raw materials and finished products in real time.

For what:

Control of the raw mix composition before feeding into the kiln.

Profit:

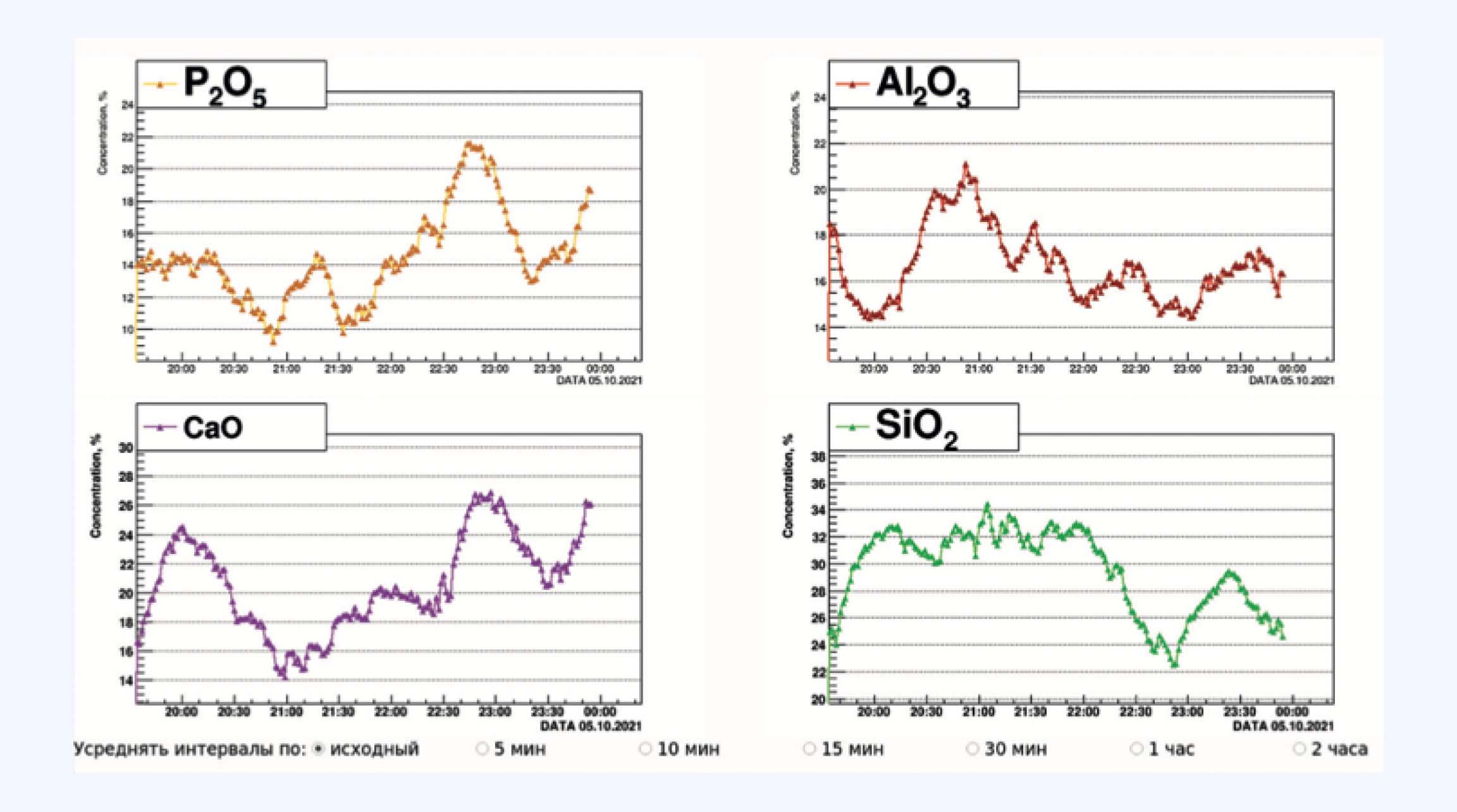

Ensuring stable oxide ratios (CaO, SiO₂, Al₂O₃, Fe₂O₃) for obtaining high-quality clinker.

For what:

Chemical composition control of the raw slurry.

Profit:

Timely correction of charge composition parameters.

For what:

Final quality control of products before shipment.

Profit:

Guaranteed compliance of cement with declared grades and standards.

The analyzer is installed under the conveyor — the entire material passes through it.

Measures chemical composition without sampling every 40-60 seconds.

Works with material of any size.

The data is transmitted to the production management system.

Continuous control of key oxides (CaO, SiO₂ etc.).

Stable quality of clinker and finished cement.

Reduced energy costs by optimizing the roasting process.

Product compliance with standards.

| Element/ Oxide | Content range, % | Measurement uncertainty |

|---|---|---|

CaO |

30 - 50 | 0,4 |

SiO2 |

10 - 20 | 0,3 |

C |

2 - 7 | 0,2 |

Fe |

2 - 5 | 0,3 |

Al2O3 |

2 - 5 | 0,3 |

MgO |

0,4 - 3,0 | 0,3 |

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание