The separator is built into the conveyor line for automatic sorting of iron ore by chemical composition in real time.

For what:

Sorting of ore into rich (with high iron content) and poor before enrichment.

Profit:

Sending for processing only ore with high iron content, reducing the cost of enrichment of low-grade ore.

For what:

Separation of ore with high sulfur and silicon content.

Profit:

Obtaining high-quality raw materials for the sinter plant, reduction of harmful emissions during roasting.

For what:

Formation of homogeneous ore batches with given characteristics.

Profit:

Guaranteed quality of shipped products and stability of metallurgical furnaces.

The separator is installed under the conveyor.

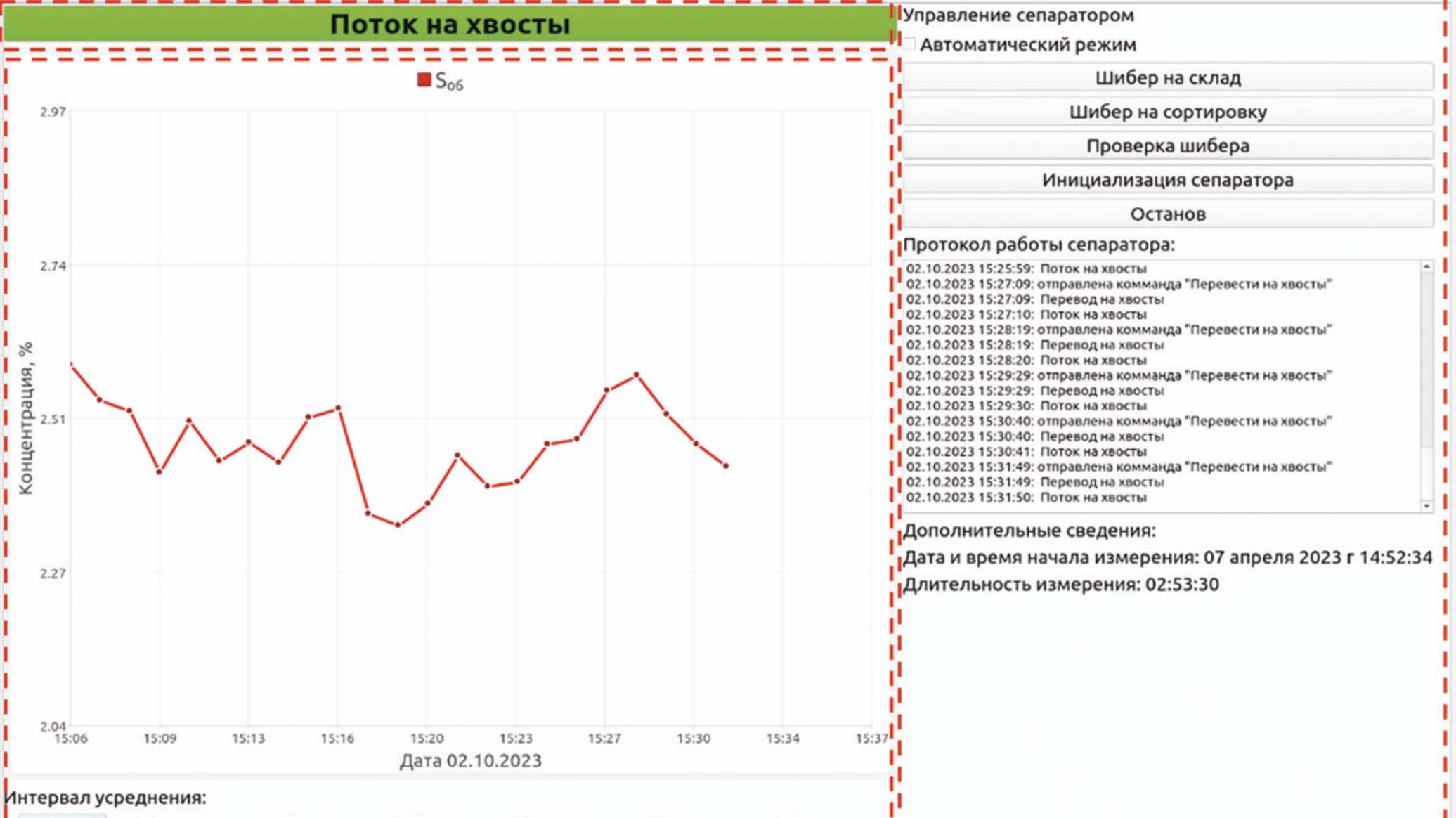

Analyzes the composition of each portion of ore without stopping the conveyor.

Automatically gives a signal to the flow transfer mechanism.

Divides the ore into several streams according to Fe, S, SiO₂ and other elements content.

Automatic sorting of ore by chemical composition.

Improving the quality of iron ore concentrate

Reduction of sulfur content in finished products

Optimization of costs for transportation and processing of low-grade ore

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание