This stationary analyzer is designed for rapid quality control of iron ore at different points in the process chain. It works with samples without preparation — just select pieces up to 100 mm and place them in the analyzer.

For what:

Fast analysis of samples from wells or quarries directly at the deposit.

Profit:

Instantly estimate iron and impurities content to decide on further exploration or sampling for laboratory analysis.

For what:

Operational check of ore from different sections of the quarry.

Profit:

Ore sorting by quality directly at the extraction site for optimal processing direction.

For what:

Control of incoming ore from suppliers.

Profit:

Quickly determine the grade of the batch and decide on its use.

For what:

Analysis of ore samples at different stages of processing.

Profit:

Timely adjustment of enrichment parameters.

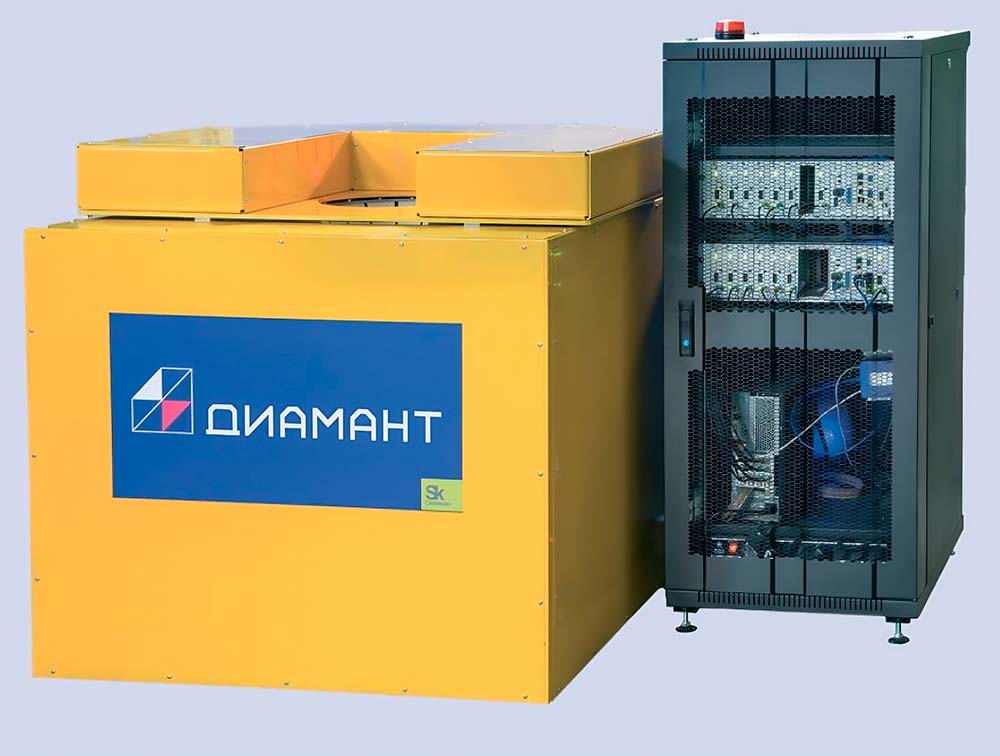

An ore sample weighing 2-5 kg is loaded into the analyzer container.

After 5-15 minutes, the result for iron and impurities content is ready.

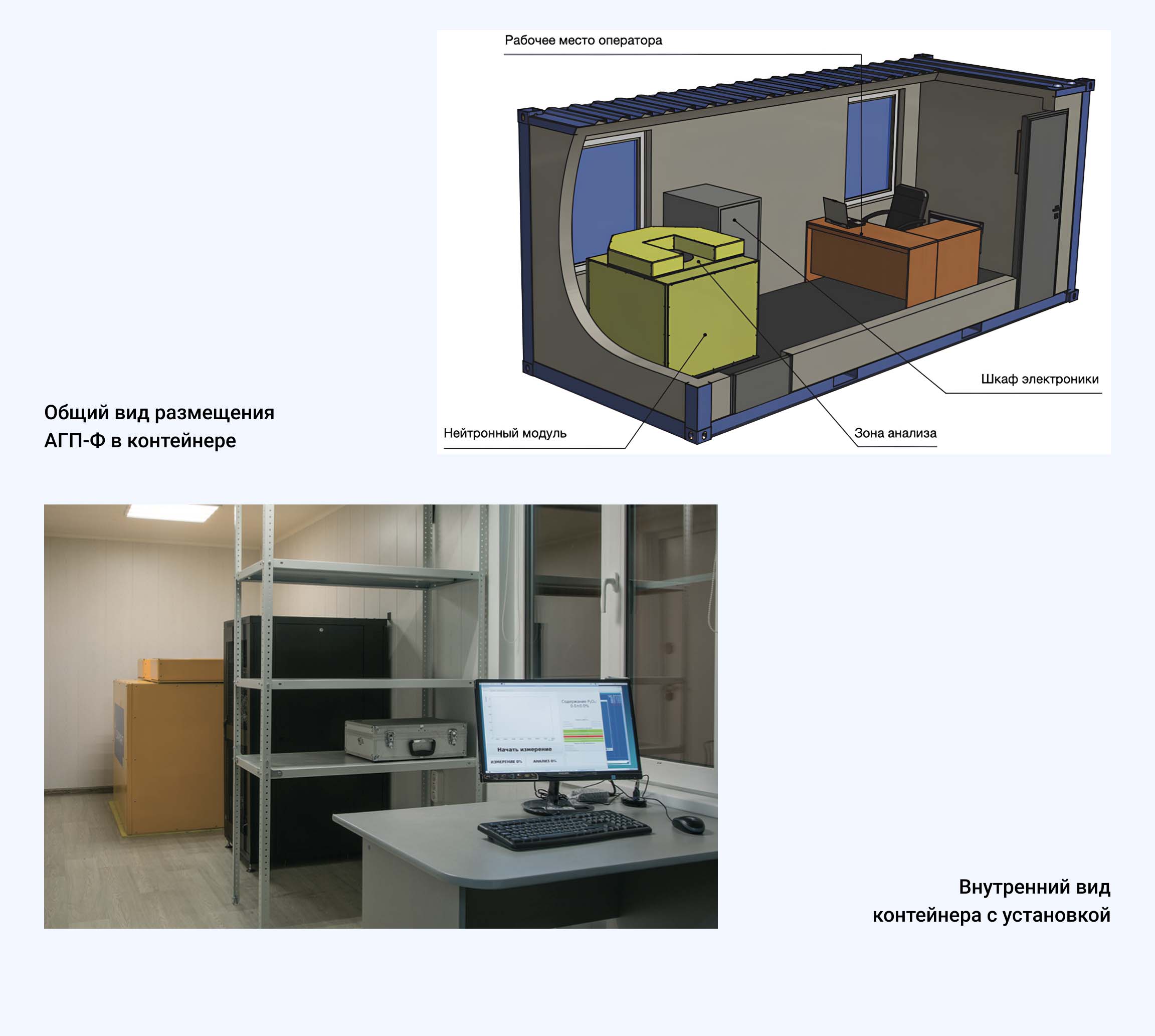

The device can work in the field in a special container.

Speed: Results in minutes instead of days waiting for laboratory analysis.

Simplicity: No need to crush and grind the sample.

Mobility: Work directly at the deposit or in the workshop.

Efficiency: Ability to make quick decisions on the spot.

| Element/ Oxide | Content range, % | Measurement uncertainty |

|---|---|---|

| Fe total | 30 - 60 | 0,25 |

Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю. Съешь ещё этих мягких французских булок, да выпей чаю.

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание

Заголовок

Описание